Give our technical sales team a call

(303) 699-1135 | (800) 456-9012

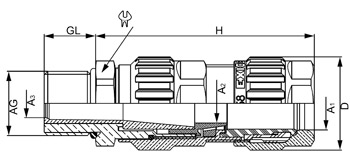

| Hole Diameter (A) | 2.48" (63 mm) |

|---|---|

| Body Length (H) | 5.69" (144.5 mm) |

| Thread Length (GL) | 0.63" (16 mm) |

| Wrench Flat (F1) | 3.15" (80 mm) |

| Cable Range 1 | 1.81 - 2.57" (46 - 65.3 mm) |

| Cable Range 2 | 1.57 - 2.22" (39.9 - 56.3 mm) |

| Clamping Ring 2 | 0.06 - 0.10" (1.5 - 2.5 mm) |

| Gland Size | 63 |

| Outer Diameter (D) | 3.54" (90 mm) |

-

Features

This Gland option is available with ATEX, IECEx, Inmetro (Brazil), Gost (Russia), ABS, DNV and CSA / cUS Approvals. Rated as Class 4418 85 – Cable – Hardware – For Hazardous Locations – US Requirements Class I, Zone 1, AEx de IIC Gb, Zone 20, AEx ta IIIC; D. Larger sizes then M75 are available upon request.

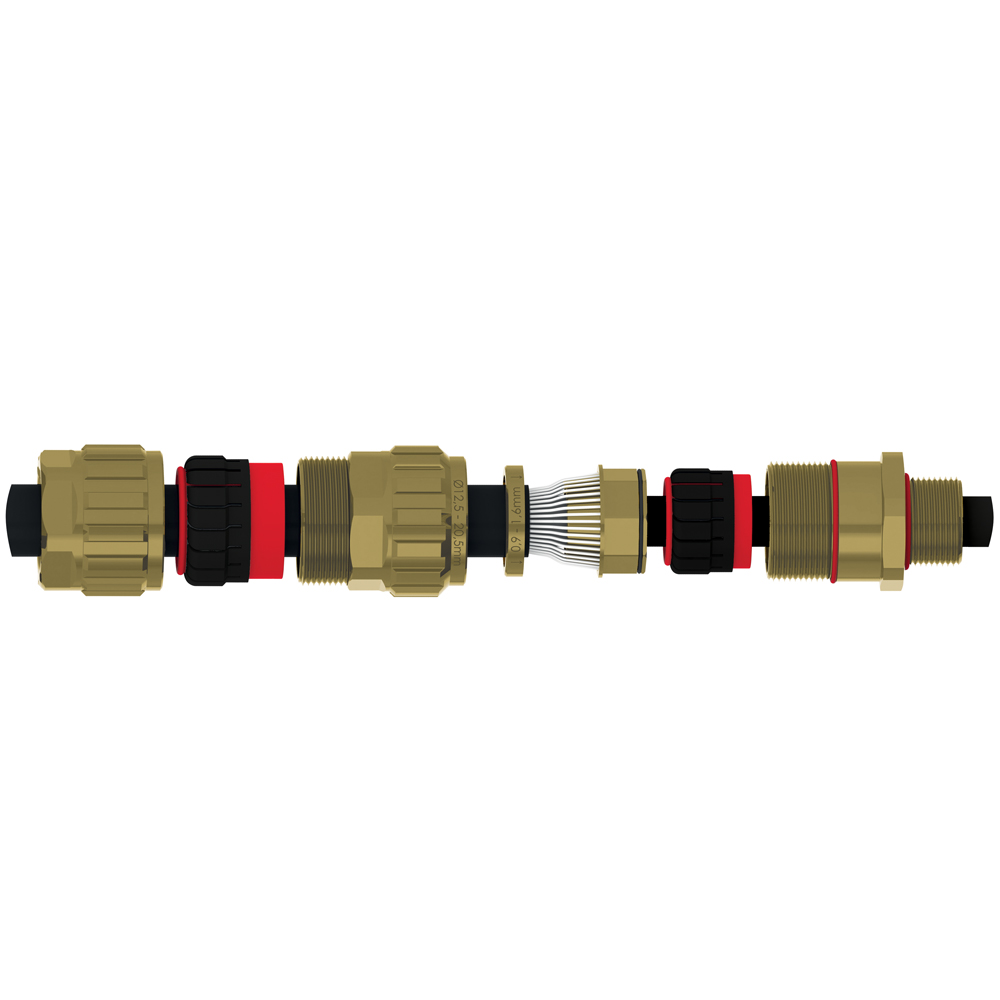

High-end Raw Brass Cable Gland for armored cables suitable for for applications in challenging hazardous locations.

Designed for all explosion proof areas with high performance regarding reliability and tightness, e.g. marine, offshore, gas conveying machinery, refineries and chemical industry.

IECEx and ATEX certified, for use in Ex-e, Ex-d areas.ATEX

- ATEX 95 equipment directive 94/9/EC, Equipment and protective systems intended

for use in potentially explosive atmospheres. - ATEX gets its name from the French title of the 94/9/EC directive:

Appareils destinés à être utilisés en ATmosphères EXplosibles - The regulations apply to all equipment intended for use in explosive atmospheres,

electrical or mechanical, including protective systems. There are two categories of

equipment I for coal mining and II for industrial applications. - Once certified, the equipment is marked by the ‘CE’ (meaning it complies with ATEX

and all other relevant directives) and ‘Ex’ symbol to identify it as approved under the

ATEX directive. - Ex-e = Explosionproof (Increased Safety)

- Ex-d = Flameproof (Combustible Environment)

Materials Part Number Key ( Last 2 letters)

xxxxx-BB = Raw Brass

xxxxx-BR = Nickel Plated Brass

xxxxx-B1 = Brass Gland with Nickel Plated Thread.

xxxxx-SS = Stainless Steel 316 - ATEX 95 equipment directive 94/9/EC, Equipment and protective systems intended

-

Materials

- Form Seal: silicone, VMQ

Operating Temperature

-60C° to 105C° (-76°F to 221°F)

CE approval CE (Certified European Approval)

CE approval CE (Certified European Approval) ATEX - ATmosphere Explosible

ATEX - ATmosphere Explosible IECEx

IECEx National Institute of Metrology, Standardization and Industrial Quality

National Institute of Metrology, Standardization and Industrial Quality PCT Approval

PCT Approval German Lloyd

German Lloyd ABS

ABS DET NORSKE VERITAS (DNV) Certificates

DET NORSKE VERITAS (DNV) Certificates CSA approval CSA (Canadian Standard Association)

CSA approval CSA (Canadian Standard Association)