Dependable Cable Glands for Panel and Control Modules in Manufacturing

As digital technology and industrial automation become more integrated into manufacturing processes, dependable panel and control modules are essential for ensuring seamless operations across multiple sectors. From power distribution to process control, these interfaces serve as the nerve center of operations. Reliable cable glands are crucial for panel and control module systems used in manufacturing processes to help assure efficiency and productive systems.

Cable Glands Secure Basic Connectivity

Cable glands, also known as cord grips or cable fittings, are devices designed to secure and protect cables entering enclosures, panels, or control modules. These small but critical components serve essential functions.

Cable Management

In a panel or control module, multiple cables carrying power, data, and signals need to be connected and organized. Cable glands provide a structured and organized way to route cables, preventing tangling or stress on the connections.

Protection From Operating Environment

Panels and control boxes often operate in challenging environments, ranging from extreme temperatures to dust, water, chemical exposure. Cable glands create a barrier against external elements, safeguarding sensitive components and connections from potential damage.

Strain Relief

Cables are subject to movement, vibration, and mechanical stress, especially in industrial settings. Cable glands offer strain relief by anchoring the cables securely, reducing the risk of connections coming loose due to mechanical forces.

Dust and Water Sealing

Quality cable glands incorporate sealing mechanisms, such as gaskets or compression seals, to maintain the integrity of the enclosure. This helps to prevent the actual infiltration of dust, water, or other contaminants into the control panel, thereby enhancing the longevity and reliability of the system.

Why Choosing The Right Cable Glands is Essential

There are many reasons why the choice of what cable glands to use in your control system is very important. Choosing a well-specified, quality cable gland provides project benefits such as:

Design Flexibility

Cable glands are available in various sizes and materials to accommodate different cable types and diameters. Manufacturers can select the appropriate cable gland to match the specific requirements of their designs, allowing for greater flexibility in cable routing and installation.

Ease of Installation

Cable glands are designed for easy installation, often requiring minimal tools. Their straightforward assembly reduces the time and effort required for cable management, thus streamlining the manufacturing process.

Reduced Downtime

In manufacturing, downtime can result in substantial financial losses. Reliable cable glands contribute to the overall performance of the process, minimizing the risk of cable-related failures and costly interruptions.

Regulatory Compliance

Many manufacturing industries are subject to stringent safety and regulatory standards. Properly installed cable glands ensure that systems adhere to these standards, avoiding potential legal and operational challenges.

Sealcon is Your Source for Dependable Connectivity Solutions

Sealcon cable glands deliver performance and reliability in a diverse range of manufacturing environments. Our extensive product line includes a diverse range products with attributes designed for specific application needs, such as:

- Low Smoke / Halogen & Phosphorous Free Products: V0 Flame Rated, Ideal for applications requiring a low smoke environment, Non-Toxic according to UL94.

- Submersible & Liquid Tight: Perfect product for a spray down or submersed application.

- Unsurpassed IP68 / NEMA 4X & 6 / 10 BAR (150 PSIG) Rating. The patented form seal (Grommet Around Cable) allows products to be installed in up to 300 ft

- Outdoor / UV Exposure: Our products are ideal for outdoors. All of our black Nylon Strain. Relief Fittings are made with a UL f1 (746C) UV & Ozone Stable Material & ACME thread.

- NEMA Installation: All of our Cable Strain Relief Fittings come with a Patented O-Ring Groove, resulting in a liquid tight seal between fitting and installation when used with a correct o-ring.

- Anti-Vibration: Sealcon’s Cable Strain Relief Fittings feature notches molded into the dome nut to prevent the dome from coming loose from the Cable Gland body. This is referred to as a safety ratchet system.

- Approvals & Certifications: Our products are UL, UR, CSA, VDE, CE, PCT Gost, German Lloyd (GL), TUV, RoHS, Deca BDE, ATEX, IECEx, Ex-e and Ex-d.

Through our extensive application experience our team can help you find the right cable glands and other connectivity products for your application.

Automated Agriculture, Robotic Farming, and the Need for Reliable Connectivity

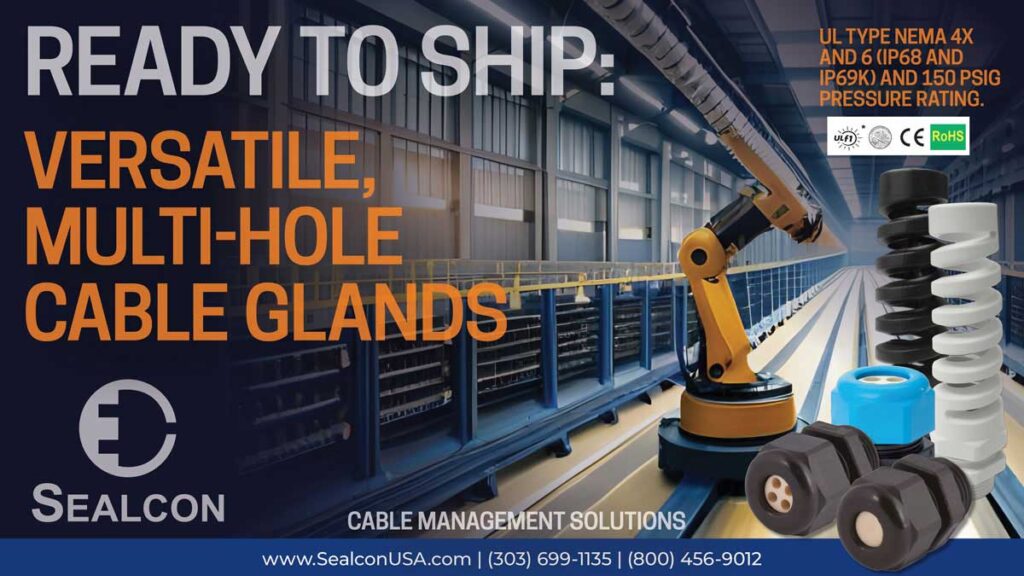

Automated Agriculture, Robotic Farming, and the Need for Reliable Connectivity  Ready to Ship: Versatile, Multi-Hole Cable Glands

Ready to Ship: Versatile, Multi-Hole Cable Glands  Sealcon Exclusive: The Game-Changing Power of DIV Rated – Fiber-Reinforced Cable Glands

Sealcon Exclusive: The Game-Changing Power of DIV Rated – Fiber-Reinforced Cable Glands