EV Fleets and Cars Drive High Demand for Charging Stations

Governments around the world are strongly encouraging the adoption of electric vehicles (EVs) through incentives like tax credits, rebates, and grants. Governmental pressure through legislation is growing for the implementation of EV technology, not only in the private sector, but for a wide range of government fleet vehicles.

The goal of reducing emissions and combating climate change is leading governments around the world to hasten the transition to EV through government mandates. For example, the city of Los Angeles is transitioning municipal fleet vehicles such as police cars, buses, and waste management trucks in its Zero Emissions 2028 Roadmap.

Other examples include:

- Postal Services – The United States Postal Service (USPS) has set a goal of replacing its entire fleet of delivery trucks with electric vehicles by 2035.

- Government Agencies – Several government agencies are requiring the purchase of a certain percentage of EVs for their fleets.

- Utility Fleet Vehicles – Off-road EVs are also being implemented, including forklifts, mowers, agricultural tractors, airport ground support equipment, and similar work vehicles.

EV Infrastructure Needed to Support Expanding EV Use

As governments increase interventions to ensure the adoption of electric vehicles, there comes a corresponding demand for adequate charging infrastructure. EV fleet operators will need charging stations that can accommodate multiple vehicles at once and charge them quickly to minimize downtime.

The development of charging stations that can charge multiple vehicles simultaneously, such as high-power chargers and charging hubs, requires specialized components and assemblies that meet application-specific challenges and requirements. A key requirement is that they must be designed and built to withstand outdoor environments. Resistance to water leakage and UV damage is essential for the connection components in charging stations.

Sealcon is serving the needs of charging station manufacturers with a number of connector products and cable glands which are ideally suited for these applications.

Sealcon Offers Cable Glands / Cord Grips / Connectors to Meet the Needs of EV Applications

Sealcon dome and flex glands provide a water-tight seal that is not only perfect for EV market applications. Not only are they used in electric vehicles, but also charging station components and assemblies. Used inside the station on components like sensing devices or metering devices, these connectors can be specified in nickel plated brass, or nylon to offer UV, ozone, and corrosion resistance.

Selacon BXA and BXI series cable glands / strain relief connectors / cord grips are environmentally compliant and come with safety ratchets built into the dome to prevent the dome top from coming loose under vibration. These cable glands can withstand a 7 Joule impact without breaking due to fiber reinforced construction.

Sealcon circular connectors are available in power as well as signal versions, and used to connect multiple devices within the equipment for easy installation, removal, and repair. In addition to power, many components within EV charging stations are also moving data. Dependable performance is critical and highly dependent upon stable connectivity.

Benefits Sealcon Products Offer EV Applications

- Ideal for Outdoor Applications

- UL Rating

- IP Submersion Rating

- Wide Range of In-Stock Sizes

- Ready to Ship

- Technical Assistance

Manufacturers of critical EV infrastructure can depend on Sealcon for high quality, reliable connectors delivered on time. Contact us to discuss your project and get a free quote.

Automated Agriculture, Robotic Farming, and the Need for Reliable Connectivity

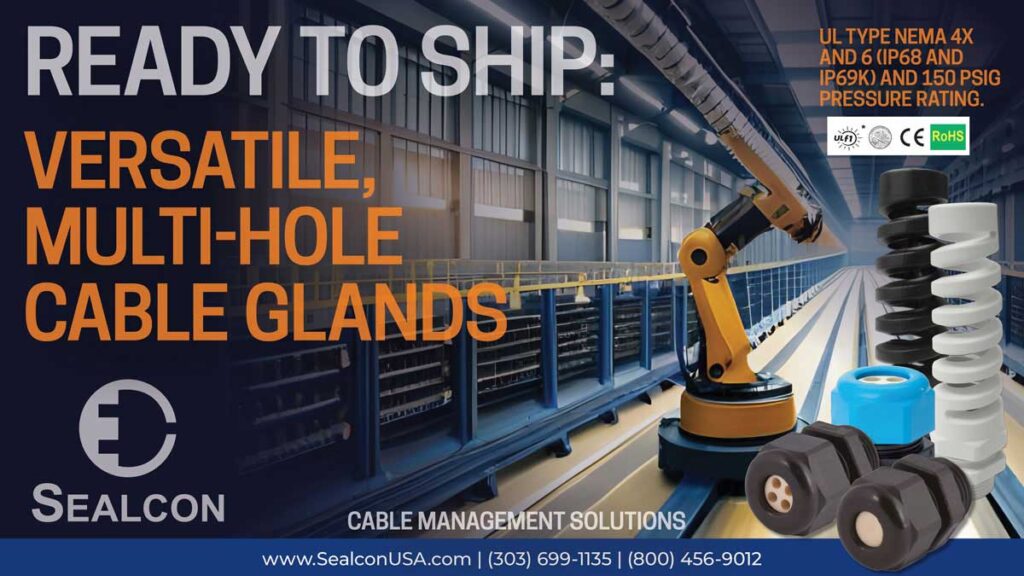

Automated Agriculture, Robotic Farming, and the Need for Reliable Connectivity  Ready to Ship: Versatile, Multi-Hole Cable Glands

Ready to Ship: Versatile, Multi-Hole Cable Glands  Sealcon Exclusive: The Game-Changing Power of DIV Rated – Fiber-Reinforced Cable Glands

Sealcon Exclusive: The Game-Changing Power of DIV Rated – Fiber-Reinforced Cable Glands