Picking the Best Marine Solutions For Today’s Demands

Covid Brings New Challenges to Boating Industry

COVID travel and gathering restrictions has led to an increase in outdoor activities such as recreational boating. According to data reported by Barrons, “total new U.S. recreational boat sales in May were the highest in a single month since 2007, with increases across all segments.”

With the effects of coronavirus most likely still lingering well into the warmer months of 2021, this trend does not appear to be waning anytime soon.

The increased interest in boating has led to a greater demand for marine related equipment, both within the marine commercial and manufacturing industry, and with those who purchase watercraft and boating equipment.

Ensuring Superior Performance for Your Marine Applications

If you’re involved in the marine industry or recreational marine activities, it’s important to pay attention and prevent any maintenance issues that may arise with your marine equipment and components. It’s critical to ensure they are equipped to combat the effects of saltwater, vibration, high-temperatures, UV rays, and other harsh conditions that make them vulnerable to corrosion, oxidization, and other types of damage.

Although the above issues are nothing new when it comes to marine equipment—COVID has added an additional challenge with the rigorous sanitation and cleaning protocols for boats and equipment.

This heightened exposure to harsh cleaning chemicals requires the need for marine components that are designed to hold up to these types of elements.

As a result, it’s critical to be sure each component is built specifically to withstand these challenges. Preventing corrosion, oxidation and other damage requires vulnerable equipment to be supported with top-of-the-line cable management components that have the key industry ratings and approvals (e.g. NEMA, IP68/69K and so on).

Reduce your liability and costs by using premium high-quality anti-corrosive and liquid-tight marine solutions that withstand long-term environmental demands. We offer products with innovative technology designed for underwater and marine requirements – ideal for boats, yachts, depth sensors, dive lights, cranes, antennas, fish locators, and more. Learn more here.

Submersible Solutions

Below are some of the important features and benefits of our marine Cable Gland solutions.

• Stainless Steel (303/316L) for Salt Water/Spray and Wash Down

• Nickel Plated Brass for Ruggedness and Mechanical Stress with Cranes, Hoists, Controls, etc

• EMI/RFI Nickel Plated Brass for Radio, Antennas, Radar, Surveillance Cameras, etc.

• Mini WADI – Small/Compact, Nickel Plated Brass/Stainless Steel for Stairwell Lighting, Cameras, etc. – EMI & High Temperature Available

• Nylon Black UL f1 (746C) UV/Ozone Resistant for Durability Under the Sun

• Unsurpassed Liquid Tight Nylon or Metal Fittings for Permanent Submersion (150 PSIG) used in Dive Lights, Dive Cameras, Pumps, etc.

• BXA* Fittings for Hazardous Duty Location – cUS Class 1 I Div 2, ATEX I IECEx

• Solutions for Onshore/Offshore & MRO Business

More Reasons to Choose Sealcon Marine Products

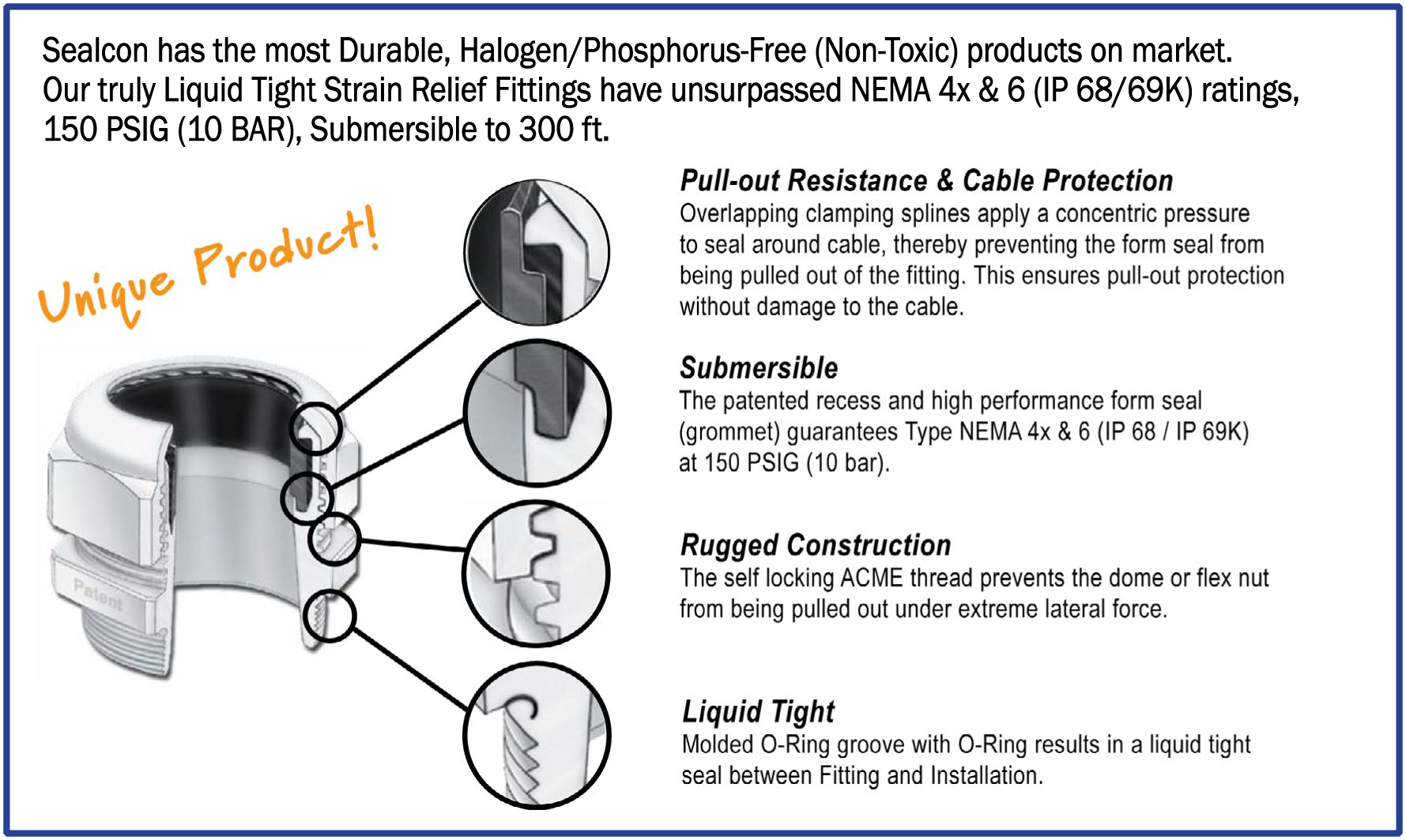

Submersible & Liquid Tight – Perfect product for a spray down or submersed application. Sealcon products have an unsurpassed IP68 / NEMA 4X & 6 / 10 BAR (150 PSIG) rating.

The patented form seal (Grommet Around Cable) allows products to be installed in up to 300 ft underwater. Our product is also spray down IP69K rated.

Ideal for Outdoor / UV Exposure – All of our black Nylon Strain Relief Fittings are made with a UL f1 (746C) UV & Ozone Stable Material & ACME thread.

NEMA Installation – Our Cable Strain Relief Fittings come with a Patented O-Ring Groove, resulting in a liquid tight seal between fitting and installation when used with a correct o-ring.

Vibration Proof – Sealcon’s Cable Strain Relief Fittings feature notches molded into the dome nut to prevent the dome from coming loose from the Cable Gland body. This is referred to as a safety ratchet system.

Feature Required Approvals & Certifications – Our products are UL, UR, CSA, VDE, CE, PCT Gost, German Lloyd (GL), TUV, RoHS, Deca BDE, ATEX, IECEx, Ex-e and Ex-d.

Ready to learn more about Sealcon solutions for your marine application?

Pick & Place Robotics Need High Quality Cable Management Solutions from Sealcon

Pick & Place Robotics Need High Quality Cable Management Solutions from Sealcon  Smart Cities and the Future of Urban Infrastructure Needs Sealcon Connectivity

Smart Cities and the Future of Urban Infrastructure Needs Sealcon Connectivity  The Backbone of the Digital World: Reliable Solutions for Data Centers in Cyberspace

The Backbone of the Digital World: Reliable Solutions for Data Centers in Cyberspace